Fentress County, Tennessee is best known as the birthplace of World War I hero Alvin C. York and as the home of the Big South Fork National Rriver, but like neighboring Cumberland County, it is also a region rich in natural stone deposits and rich in family-owned and operated stone yards and quarries. This predominantly rural area has been hard hit in recent years by economic downturns and by a loss of traditional artisans who have either moved away or found work in other fields, but Patrick Garrison and Johnny Presley, co-owners of Rocky Ridge Stone Company in Crossville, are making every effort to preserve Fentress County's heritage while at the same time providing their clients with the highest quality natural stone available in the region.

Located in Crossville in Cumberland County, Rocky Ridge was profiled in the January issue of Slippery Rock Gazette. That article spotlighted how Presley's grandfather's quarry had been reinvented for the twenty-first century through the latest technology combined with a healthy respect for both traditional methods and craftsmanship, and for the environment. This same approach is now being taken with Rocky Ridge's recent acquisition of a unique Tennessee Bluestone quarry in Jamestown.

The Jamestown Quarries (formerly Clayborn Quarries and then C&C Quarries) have been in Jeff Clayborn's family for three generations, and he has stayed on under the new owners to manage the operation. As someone who literally grew up in the quarry, Jeff is an expert on Tennessee Bluestone, especially the best methods for harvesting it. Bluestone is unique, not just because of its deep color, but also because of its uniform thickness.

"It's so consistent," Jeff says, "that it comes out naturally in sheets ranging from three quarters of an inch to two inches thick all the way across the quarry." This consistent thickness combined with lengths that average four to five feet-but that may be as long as ten feet-means a greater yield of stone. "Because of these longer spans, you can get more mantles and stone hearths."

The yield is further increased by how easy the bluestone is to remove. As Jeff puts it, "We don't have to take out the whole bank. We can take the rock away layer by layer." This also means that the quarrying has less of an environmental impact than traditional blasting, so that the Jamestown operation fits with Rocky Ridge's eco-friendly philosophy, and the bluestone is among those products offered by Rocky Ridge that are green approved.

Jeff notes that the ease with which the bluestone can be quarried means that "it's easier on the masons and gives clients a faster turnaround on projects."

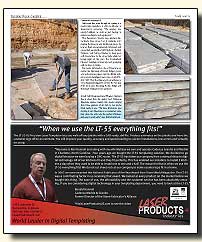

Top: Tennessee Bluestone Flagstones and mixed stone retaining wall from a private residence in North Carolina are all Rocky Ridge Stone products, showcasing the beautiful variety and utility of the Jamestown Bluestone and Rocky Ridge Grey and Brown natural stone products.

Above: The rolling hills of Fentress County, Tennessee cover a wealth of Bluestone, laying close to the surface in deposits of a uniform thickness. Quarrying the stone is easier, and has a lower environmental impact than traditional blasting.

Patrick Garrison echoes this sentiment when he calls Tennessee Bluestone "an ideal stone for fabrication. We're able to bring it out in slab form, and it's ready to go." Besides its decorative use in mantels and hearths, the lengths of the slabs and their even thickness make it perfect for large scale outdoor projects. Patrick mentions in particular its suitability for hot tub surrounds and patios which require a particularly wide radius. He also adds that the uniformity of the stone layers "makes it much easier to estimate square footages."

While Pennsylvania Bluestone is quite well known for use in architectural elements and as a paving stone, Tennessee Bluestone stands to become just as prominent as more people learn about its availability and versatility. Jeff Clayborn proudly mentions two of the major projects that his family's quarry supplied stone for over the years - some of the original paving stone used at Dollywood when the amusement park was built in Sevierville, Tennessee in the mid-eighties and the swimming pool constructed for the Atlanta Olympics in 1996.

Now with Rocky Ridge Stone Company's ownership, the quarry stands poised to reach a still broader consumer base, especially as Rocky Ridge's business is growing at a steady pace. The firm has recently added clients in Colorado, Maine, and New Jersey, and being able to offer a unique, top quality product at an affordable price means that the company will only continue to grow and achieve a national reputation.

No matter how large Rocky Ridge may ultimately grow to be, what will not change is its commitment to local artisans, fabricators and local businesses.

Jeff notes that even though his quarry is a small scale operation, it still contributes to Jamestown's economy. "We employ two palette builders, as well as just having to replace machinery and equipment."

The Jamestown Quarry may produce distinctively blue stone, but it certainly isn't singing the blues in any traditional sense. As long as there are experienced, informed, and committed people like Jeff Clayborn, Patrick Garrison, and Johnny Presley to keep pace with innovations in the stone trade while not losing sight of the past, the Cumberland Plateau's heritage of masonry and quarrying will continue to thrive.

For more information about Bluestone as well as the full range of Rocky Ridge's products and services, please visit its official website www.rockyridgestoneco.com or call 931484-7158. Visit the Slippery Rock archives to see the January 2010 issue, also featuring Rocky Ridge and their Crab Orchard Stone products.

")

")