Success in the stone industry can be a matter of cultivating both roots and branches. James Rgers is the owner of J & J Stone Fabrication, LLC in West Monroe, Louisiana. It is a business rooted in the strength, loyalty, and dedication of family.

"The company has been in business for six years," he said. "I have been involved in stone work since 1989. It has grown into a family business."

The advantage of relying on family in run ning a business is "knowing that I can trust someone," Rogers said. "I have got some excellent family members that are working in the business. They understand the business. They understand what we need to do to be successful. They work very hard to make that happen."

Rogers has four adult children who work for him. They perform a variety of tasks throughout the company. "I have an office of three people," Rogers said. "My daughter is officer manager here. My son is bookkeeper. He helps manage the accounts receivable and the accounts payable. I have a secretary that handles sales.

"My oldest son installs 90 percent of our business--the slabs of granite and marble. The other son cuts all the stone that goes out."

In all, J & J Stone employs about 14 people, Rogers said. "I have a shop crew for fabrica tion. I have a crew for installation, and I have three ceramic tile crews. They work every day. I have four people in my shop that rotate out on installations."

He grew up with the idea of family involve ment. "They all work in the business with me. I grew up in the ceramic tile business. My father and my grandfather were in the tile business. I'm third generation.

"I've been in stone since it became popular back in the 1980s. We've just grown our little business here. It's still growing. We're in the process of buying some equipment for our shop -a Pro-Edge, and a Wizard from Park Industries -to increase production."

The current complement of tools in the J & J Stone shop includes a Matrix bridge saw, an Edgemate 100, and a Hercules ® router for shaping edges, Rogers said. "We started with a (circular) saw, and it's grown over the years. That's all we had back then. We'd cut it by hand with a saw. We'd edge it and shape it and position it. We've come a long way since then." Roger's son Josh added, "Our new Park Wizard has just arrived, and we have plans to install the Park Pro-Edge before the end of the year, to keep up with all the profiling jobs."

Rogers came into the stone industry in 1989. "That's when the stone business was getting started in our area. I went to Dallas, followed a couple stone guys around, came back, and called myself a stone man. I learned as I went. I'm self-taught. Back then there weren't a lot of people to learn from."

In 1998, he moved to Mississippi to work for a company already established in the stone industry. It was family, however, that brought him back home and led him to found J & J Stone. "My oldest son wanted to pursue the stone business, so I said 'I can't do that for you in Mississippi, so we're going home,'" Rogers said. "I came back here and picked up the pieces from before I left.

J & J Stone specializes in high-end applica tions such as custom bathrooms and kitchens. "A very small portion of our business is com mercial work," Rogers said. "We don't do much. About 75 percent of our business is the 50-to-60-year-old age group their kids have left home, and they want to remodel the house before they retire.

That's probably the biggest segment of people we do business with in this area."

In addition to a shop, J & J Stone has a showroom "where we provide a wide range of types of stone and tiles to the customer to choose from," Rogers said. "We have a pretty broad spectrum."

Rogers buys stone and tile from about a dozen suppliers throughout the South. On the tile side, the business traffic is more in glass and stone tiles than ceramic. "We tend to do more stone than anything else," he said. "We seem to be in that particular niche of the market where people come when they are looking for stone products."

Although he has dedicated employees to rely upon, Rogers is not content to take a background role in running the business.

"Other than owning the place, I go out and do the field measuring and meeting with customers and contractors in the field and make sure the job goes smoothly," he said. "I enjoy that. I'm out every morning. I'm making my rounds every day to not only meet our employees on the job but to meet with the customers and the contractors."

Sitting in an office all day does not appeal to Rogers. "No, that's not my world," he said. "I'm not a number cruncher. I can't sit at a desk and be there all day. I have people that do that for me."

One of the most memorable jobs that J & J Stone has undertaken was distinctive because of the scale. "The most unusual project for us was probably a job we did in Shreveport, which is about 100 miles away," Rogers said. "We put 52 slabs in a house. We put 30 of them in the master bathrooms. They wanted slab stone from floor to ceiling. They had 10 foot ceilings. We did three bathrooms that way. We wrapped them all the way to the ceiling and all the way around. We don't typically do that type of job. We may do a slab shower but not the whole bathroom."

Word-of-mouth and a good reputation are the cornerstones of J & J Stone's marketing approach. "We tried a little bit of advertising," Rogers said. "I couldn't tell it was making any difference as far as customers coming through the door."

Concentrating on a small geographic area gives J & J Stone an advantage when it comes to referrals. "Our business is concentrated in the Monroe, Louisiana, region," Rogers said. "We cover a radius of about 60 miles around Monroe.

"We're in a relatively small area as far as population -(there are) about 100,000 between the two cities. The bulk of our work is with people who know or have heard about it because the city is just not that big for us to disappear into. In our area, there are probably a dozen fabricators. The reason we don't do a lot of commercial work is we just don't have a large city with lots of commercial buildings that require construction in our area."

Rogers said his long-term goal for the company is to diversify its offerings. "I have discussed with my family that I would like to see us take it to another level. Being a fabricator could possibly lead us more into a supplier type application. We can provide not only a service, we can provide a wide range of products for people in the area. That's the next level we're talking about working towards.

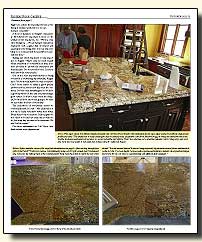

Above: Josh Rogers polishes one of two seams on a large wing-back island. Josh is using a five-step process starting with a coarse, 100 grit TalonTM Twist-Lock Turbo Wheel. When polishing seams on the jobsite, Josh sets up a water dam and applies just enough water for the first four wet polishing steps, to minimize clean-up. Below, right: J&J sawyer and installer Shannon Knighten trims a slab with their 6-year old Matrix Sebring Bridge Saw. "The Matrix has been a real workhorse for us, but we've also just gotten a Park Wizard and a Pro-Edge to handle all the profiling jobs," says Josh Rogers. Below, inset: Diano Real tub surround complements the master bath in a recent large project for a residential customer in Monroe, LA.

Right now and for the immediate future, we're trying to increase production so we can increase our profits."

A focus on family is not Rogers' only priority. He believes it's important to focus on the welfare of the employees, too. "We're a very close knit group. ... We are trying to treat all my employees with a great deal of respect and appreciation for being here. It is my responsibility to not only provide for myself but to provide for them."

Taking care of his employees is very important to Rogers. "That's why we work toward where everybody is comfortable in their positions and able to provide for themselves and their families. It's not just about me. I have to think about the other people."

One of the most important factors in being successful is cultivating dependability, Rogers said. "We work very hard to be very consistent. (J & J Stone strives to offer) a good quality product and be honest and fair with the customer. It's been very rewarding for us. We have a good reputation in this area for performing a good service. It doesn't mean we're the cheapest, but they know that we're going to do what we say within the best of our ability."

The importance of consistency cannot be over-emphasized, he said. "My philosophy is you try to make tomorrow better than today. Every day you try to improve. I tell my guys we don't have to be the best every day at what we do, but every day we need to be consistent. We can't be hit or miss."

For more information on J & J Stone visit their website www.j&jstone.net

Above: This super-sized, 6cm kitchen island used a full slab of Terra Nova Granite with laminated, double ogee edges and a bowed front, shaped and profiled by hand. "The island was so large and fragile that we actually used a hydraulic cart (from Braxton-Bragg) to bring the island into the house. Luckily, the house had a double front door, so we just rolled the cart right in. That's the only time we've used the hydraulic cart to bring a top onto a job site, but it sure was easier to roll a full slab in than carry it!" said Josh Rogers.

Below: Before and after views of the wing-back island shown on page 2. After working through four grits of the TalonTM Twist-Lock system, Josh finished up using a 1,000 grit ceramic pad. Used almost dry, Josh uses the built-up heat of the ceramic pad to bring back the polish to match the rest of the island. "It is not unusual that we'll have to bring in a really big island in several pieces and assemble on the job site. I've been taught by some really experienced installers, and also developed a technique that works for me over time by experimenting with different grits and pads."