Is Laser Templating Right for Your Shop?

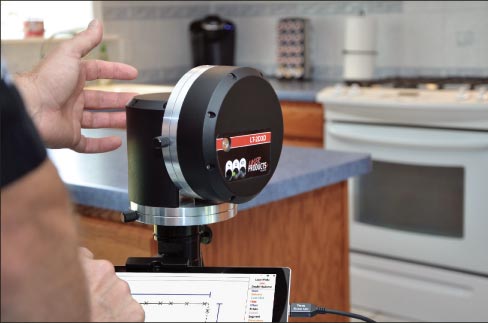

A Review of the Laser Products’ New LT- 2D3D Laser Templator

Peter J. Marcucci

Photos Courtesy Laser Products Industries

|

|

“Our product is more efficient in what it does with that data. Our software, and this is a biased opinion, is much faster, easier to use, easier to draw with and easier to email. When talking from a speed perspective, from the minute you get to the customer’s house to when your shop gets the data, we are substantially faster measuring and transferring with our software than simply the acquisition of data with other systems.” |

|

|

|

Comparing the LT-55 and the LT-2D3D: “If it takes a half hour to measure a kitchen with the LT-55, with the LT-2D3D, you’re still saving 10 minutes each time, which adds up, time after time. Another thing that the LT-2D3D ads is the ability to capture all the data in the room from one setup.” |

|

|

“There are a bunch of ways to double check all measurements, so that when it’s being fabricated, those countertops are going to fit perfectly, greatly reducing installation time.” |

|

|

In addition to offering hands-on training, Laser Products has a wide range of set-up and training videos available through their website. |

|

|

Laser Products offers on- the-jobsite training for one to two days, or more, and will train customers through the process from digital templating to fabricating the product. |

|

|

Above: The LT-2D3D is very compact, and comes with accessories in a sturdy Pelican hard case. |

|

|

Above: This curved soffit was traced and a template created to fabricate a matching desk area, below. “The company that did the lighting didn’t have any way of measuring the soffit once it was raised to the ceiling. Luckily the countertop fabricator was there at the exact same time and was able to help them out.” |

|

Rich Katzmann: “There’s a lot of industry consolidation going on where the smallest shops, to a certain degree, are being pressured by the automated shops. We are riding this wave of shops being automated. An MIA study a few years ago showed that 35 percent of the fabricators not currently automated are seriously considering going in that direction, and if you’re using a CNC saw, you’ve got to have digital input. You cannot use stick templates unless you bring them back to the shop, digitize them, and then you transfer the data – a waste of time. “It is significant that ten of the last eleven “Fabricators of The Year” chosen by Stone World Magazine use our laser. We love that. What’s neat about these fabricators of the year, is that they are not all high volume guys. If you are a high volume guy and all about efficiency, you’re going to want to buy our laser. Furthermore, if you a custom guy and all about accuracy, you’re also going to want to buy our laser. So we like the fact that we are not pigeon holed into one type of fabricator. Everyone can use our products. ” |

Whether your shop is big or small, high volume or custom, if you’re still on the fence about hard templates versus digital templating, this story is for you.

The tried and true stick or paper template has been with us for decades. Some wood, screws and a few simple tools got the job done. So why not stick (pun intended) with doing it this way? The development team at Laser Products Industries (LPI), along with vice president of sales and marketing Rich Katzmann, have other ideas. Katzmann is totally excited about this next generation digitizer, and chances are that by the time you finish reading this you will be, too. You be the judge.

Features

The LT-2D3D is the company’s latest generation laser templator, and as of July was updated to version 4.1. Possibly the coolest new feature of this laser is that unlike the LT-55 which used a bubble, the LT-2D3D is digitally leveled, assuring the user of a quick and perfect setup every time, explained Katzmann.

“Generally, when you begin, you shoot a plane, and what that plane does is allow you to go from 3D mode to 2D mode. With most of our customers being in the countertop industry, 2D is the appropriate mode for them to be in. However, with it being a 3D laser, you can shoot your data at any level. If you’re obtaining your data points (measurements) from the cabinets and walls, as opposed to our older LT-55 2D version, you no longer have to raise or lower the tripod and are able to shoot under or over the cabinet including full height backsplashes. Moreover, you’re able to measure all data points from one location.

“Another new feature of this product is an industry-leading laser with low current draw. We’ve also built in enough juice (battery power) so the customer can begin using it on Monday morning and it will maintain its power throughout the week. Then, when Friday comes along, they can recharge it and it’s good to go again on Monday. We’ve also increased the data speed by 30 percent, so if you’re on a jobsite templating, the time to capture the data is much faster than our previous versions. This helps keep the user in the flow of templating, and not waiting for the beep before going to the next data point. We’ve also partnered with Microsoft and integrated their Surface Pro 4® into the system. In the past we had used previous versions of the Surface Pro and then switched over to a different company. The Surface Pro 4® is an extremely fast tablet with a high resolution screen, and has allowed us to continue to enhance our software because the tablet can respond how we need it to. It’s a great tablet, and we are happy to be back with Microsoft.”

Benefits

According to Katzmann, the core function of this laser is to rapidly acquire data points with easy to use CAD software. The software has normal features that template makers have used in the past, such as adding a backsplash, dropping in a sink or centering a cooktop. Everything is in English, making it very easy for new users to get up to speed, Katzmann said.

He added, “We don’t want them to have to learn CAD to use our laser system. So we’ve gone to great lengths to make sure the software is easy to use. Once you’ve acquired the needed information from the customer and are setup, as far as data goes, it generally takes less than ten minutes to template. It’s a very rapid process. You then simply finish the drawings by adding edges, seams, cutouts, etcetera. This takes between five and ten minutes. So it is a very quick process taking about 20 minutes total from setup to a finished drawing.”

There’s one more benefit that’s worth mentioning: emailing the finished DXF file back to the shop, explained Katzmann.

“We absolutely promote template makers emailing the job back to the shop before leaving the jobsite. They can send that DXF file, that’s CNC ready, to the shop. So if the shop wants to order the material or get back to the customer with an estimate, they can do that while the templator– is on his way to the next job. It’s a much more efficient process than the old manual way using sticks and glue, assembling, gathering everything up and driving back to the shop. With our system, it’s a real-time exchange of data, so the shop can get going on the fabrication.”

What About the Small Manual Shop?

So far, the LT-2D3D sounds great, but a lot of shops start small and build incrementally. So we asked: what about the shop that has only a few employees, cuts on a simple bridge saw and uses routers or hand grinders for their edges. Can your laser be incorporated into their production, or do they need to wait for that new CNC router or saw?

“That’s a great question,” said Katzmann. “We supply these shops with a vinyl plotter, and the data that’s emailed back to the shop goes into this plotter. The shop prints out the vinyl templates, places them onto the slab and cuts. So there is still a lot of savings. No longer are you cutting wood, dragging around tools and running back to the shop with breakable templates. There’s no need for a large gas guzzler anymore either. You’re now using small fuel efficient vehicles to carry a laser that’s the size of an airplane carry-on, and able to template more jobs in less time. Moreover, your business can grow right away without adding additional staff.

“We’ve done extensive research on return on investment (ROI), and generally what we’ve figured out is that if you’re a manual shop doing more than 150 square feet per week, your ROI will be payed back in six to nine months and used toward your next investment.

“Another great element of the product in this situation is that it’s an intro to automation. Before a company goes out and spends $200,000 to $300,000 on a CNC saw or router, they can stick their toe in the water by starting with digital templating. We love that, and it’s a nice transitional piece that they can use before spending the big bucks. They can get used to the process, and then go a little bigger.”

If the ROI for a smaller manual shop is six to nine months, what’s the ROI for an automated shop?

“When a shop is fabricating about 1,000 square feet a week, the ROI is as quick as two or three months. It really depends on what changes the company goes through due to digital templating. Right out of the gate they are going to be able to more efficiently template and fabricate jobs and realize an immediate 20 to 30 percent cost savings by doing it with our system, versus the old way.

“An additional benefit is that we tend to quote about a five percent reduction of waste. There is no misreading of a tape measure, and you know that everything in the software is correct. There are a bunch of ways to double check all measurements, so that when it’s being fabricated, those countertops are going to fit perfectly, greatly reducing installation time.

“There are benefits from the customer’s perspective, too. For example, when a customer sees our laser, a beautiful piece of professional equipment in their house collecting data, it’s very reassuring for them. Add that to the fact that it helps to not disrupt the customer by bringing in wood, cutting, making dust and noise and removing the old countertops. The process is simplistic and very efficient. Image is not everything, but it is very important. With this setup, your template technician exudes professionalism.”

Training is the Other Part of the Equation

“Training is a key component for us,” continued Katzmann. “We believe that the only way a digital templating system can be implemented effectively after the sale, is for one of our six trained professionals to go to the jobsites with that company’s templator for one to two days (more if needed, but it usually isn’t). We’ll template with them, and we’ll go back to the shop and fabricate the product, too. It’s all done with a salesman that has been doing this his entire life.”

Offering a State-of-the-Art Warranty

There is a one-year, no- questions-asked warranty Katzmann explained. “Once you buy the system, you can literally run it over with your truck and send it back – but please don’t do that! LPI will immediately send you a loner and then fix your unit for you, all under warranty. There’s no ‘sorry, you’ve abused this,’or ‘It’s not covered under warranty,’” said Katzmann.

“LPI knows you’ve made an investment in their product, and their biggest goal is that it’s available to you when you need it, period! They manufacture their product in the southwest suburbs of Chicago — all but a couple of parts are US made — so it’s very easy for them to take a unit that’s been damaged and get it back to you. Everything is assembled in the U.S., and they take advantage of that by offering a very liberal warranty program.

A Laser-Focused Future

“There’s so much energy and excitement in our industry right now, and I feed off of it,” continued Katzmann, “But the future, that’s what really gets me excited. We’ve just announced a distribution agreement with Slabsmith. Our two products fit very well together, and we are becoming more and more aligned with them to make sure the data transfer between our system and what Slabsmith provides to a fabricator works seamlessly.

“I was at the Verona show last month, and while talking to the machine manufacturers, none of them have ever seen the amount of sales numbers that they wrote up at that show.

“It’s just a really exciting time to be in this industry. And frankly, our product is top shelf, with no negatives.

“We always think about what are our flaws and what we can improve on, and there’s not a lot. It’s mostly new features and new functionality requests that our customers bring to us. With an install base of over twenty six hundred fabricators, we have great ideas coming from our customers literally every day. We don’t want to be changing things every month, so we try to hold our software releases to once every quarter year.

“I can’t announce it yet, but we also have a major new product coming out at StoneExpo in Las Vegas. It’s very new and exciting and will be available January 2017. We are trying to coordinate all future new product announcements with the trade shows. We feel that it’s a very effective way to get the word out there. So there’s lots of great new stuff coming out both hardware and software related. Our core customers are obviously stone fabricators, and all of our new products will be related to this industry. From the mom and pop shops to the biggest, everyone needs the best products, and we offer those products. It’s what we’re all about, and a great time to be in this industry. I love it!”

For hands-on learning, visit Laser Products at StoneExpo in January or visit their website at www.laserproductsus.com, or call 877-679-1300.