All Slab Fabbers: A Rock Group with a Different Groove

Fabricators Helping Fabricators

Peter J. Marcucci

Photos Courtesy Chris Hildebrand

It has been said by some pretty astute folks that the true sign of an expert is when his or her mistakes still look good. Unfortunately, getting to this level requires years of trials and scores of mistakes. From receiving slabs off the truck, to installing the final product, there are hundreds of things that can go wrong. Knowing them is the key to avoiding them.

|

|

All Slab Fabbers held their first workshop in 2019. The inaugural event was attended by about 150 fabricators, and several stone industry vendors. |

|

| Geoffrey Gran, Countertop Factory Midwest, hosts All Slab Fabbers’ first Facebook Live event in April 2020, speaking on developing shop metrics, running lean, and fielding questions on current industry issues from the participants. |

Regrettably, in a busy production environment, experienced coworkers, diligently doing their part, sometimes cannot keep an eye on their less experienced counterparts. Hence, old mistakes are sometimes revisited, and production is slowed.

Understanding these setbacks that silently await the unsuspecting craftsman is the forte of Chris Hildebrand, Founder and President of Affordable Quality Marble and Granite in Aiken, South Carolina. With his many years in fabrication and a long background in heavy equipment, Hildebrand knows all too well the benefits of proper training, and recently created the All Slab Fabbers FaceBook group. What is the All Slab Fabbers, you ask? Well, it’s a group of hands-on fabricators, from all levels of experience who are brought together, either online or in person, explained Hildebrand.

“There were a bunch of people who had followed me online for years and years, and a group was created, because I had a bad experience with a machine company. I didn’t want people to make the same mistakes that I had made, and I wanted to get the word out. This group then evolved into fabricators helping fabricators, which was the whole point of me doing what I was doing.

“Well, the next thing I knew, these fabricators were talking about different types of machinery. Things like what machines are out there, what features to look for, and what to expect during a purchase. Then, during June 2019, we officially started the All Slab Fabbers, and within three months we were up to almost 1,500 members.”

|

|

Above, Left: All Slab Fabbers group members also post in-progress updates, photos and videos on notable projects from their shops. Above, Right: This recent poster asked for help identifying a mystery problem with a dark, spreading stain on marble. The most likely culprit? Stain is coming from underneath, due to oils leaching from plumber’s putty. The faucet was installed by a third-party plumber. |

|

|

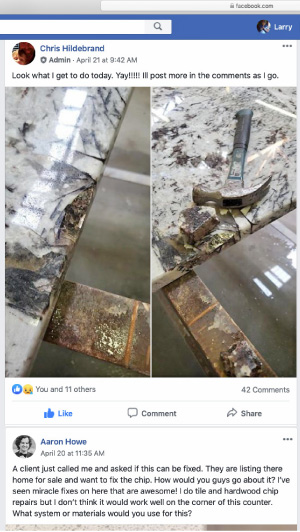

Networking on Facebook or face-to-face, and offering advice among their members spreads best practices and helps fellow fabricators find the best solution to common problems from mitering, to working with new materials, to chip repair.

|

|

|

Above: Chris Hildebrand, Affordable Quality Marble & Granite in Aiken, SC helps moderate the All Slab Fabbers Facebook group. In less than a year, the group has swelled to over 3,000 fabricator members. Chris says, “It's all about fabricators helping other fabricators.” |

|

|

From shops offering masks and supplies to another shop during the COVID-19 crisis, to discussing OSHA standards for silica exposure and how to limit it, All Slab Fabbers takes on the simplest to the most complicated questions, daily, said Hildebrand. “There are so many things that are discussed within the group. Anything you can think of, our members will help find solutions for. Many times we’ve had discussions about how to cut quartzites and what blades to use, what sealers to use under different situations or how to use materials better. “The safe handling of materials in the shop or on the jobsite is also often discussed. For these types of problems, we encourage them to use Omni Cubed products, especially their Sink Hole Savers. There are so many great examples of our member fabricators helping others. I’ve even had people visit our shop looking for information about our machines. We're happy to help others over the same hurdles we’ve faced.” |

From Concept to Facebook

Realizing he had a great concept, Hildebrand began doing a little advertising, and specifically brought in tile tradesmen. “We wanted to get tile people into the group, because porcelain slabs have been coming on hard, and we wanted their experience. The next thing I knew was that we were up to 2,000 members, and we are currently up to just over 3,100 members. Not bad for just over a year. It’s been a great place for tile setters, fabricators and the people in the construction industry to gather to share problems and solutions. It is now growing organically, and there’s no need to push the growth at this time.”

In September of 2019, the All Slab Fabbers had their first workshop at Hildebrand’s shop. The turnout was surprising, he recalls. “We were expecting 50 to 75 fabricators here, and we wound up with about 150. I had been working with a couple of porcelain suppliers, and their complaint was that nobody would take the time to learn how to cut it and play with it. So the focus of that workshop was on porcelain.

“Being the type of shop that we are, we fabricate everything on what I call a ‘locked schedule.’ This means that everything we are working on is a week and a half out to installation. We are never in a rush, and this gives us the time to test a new blade, a new bit or a new material. I’ve always tried to stay ahead of the curve, and when something new comes out, I want to know about it! Manufacturers also want feedback, and without it, they don’t know how to make their products better. We weren’t scared. I’ve dealt with fragile stone my whole career and we’d been testing and testing and testing porcelain, and decided to bring in people and show them what we had learned. We were also looking to get insight from others who had worked with it. One thing that people don’t understand with porcelain is that you’re not supposed to use epoxy or acrylic when gluing miters. Urethane glues are much better because they dry soft, not hard.”

With their first successful workshop now behind them, the All Slab Fabbers did have another workshop planned for May 2020 but, unfortunately, due to COVID-19, this meeting has been rescheduled. However, not one to be denied, the group came up with an alternate idea.

“We decided, because we canceled that workshop, that we were going to get a couple of guys together and do some sessions on Facebook Live and see what kind of responses and participation we get and try to stay ahead of the game. It actually was Jesse George’s idea (AG Stone Granite and Cabinets, Atlantic Beach, FL) to do some instruction videos on line, and it ended up being an information video, instead. Our presenter was Geoffrey Gran, of the Countertop Factory Midwest. We hope to keep doing these- I think it was very well received.”

When asked if All Slab Fabbers is a paid membership or is it free, Hildebrand said, “You might be surprised. It is completely free for fabricators to participate online, The only cost to our members for workshops is their travel expense, and we can usually get blocks of rooms at a reduced rate. However, we do invite a number of sponsors to come, which helps to offset the cost of running the workshop.

“For example: if we expect 150 people, we’ll invite 20 sales people. They may consist of machine makers, suppliers, and vendors such as Braxton-Bragg, and anyone in the stone industry. I’ll put the word out, and when there is a workshop coming it is first come, first served, and they can talk and give demonstrations on their products.”

Hildebrand did make a very strong point very clear, though, and that is that they do not have any direct sponsors for the group itself or any paid advertisers. “We did start a separate online group off to the side called, ‘All Slab Fabbers Vendors’ for companies to advertise there. We do try to drive more and more traffic to it, but we keep (all) sales stuff out of the group, because we’ve seen too many groups out there overrun with advisements. This is one of the reasons that we’ve grown so fast. We also have no sales people or manufacturers moderating the group. It’s just fabricators, all about fabricators, and that’s the way we are going to keep it.”

Looking Down the Road

“We are going to do a little bit of everything in the coming months. With everyone on a downturn, due to the virus, a lot of companies and their people don’t know how to prepare for slower months ahead. We’re also going to talk about ways to increase revenue as well as the cost of acquisitions.

“As for where the All Slab Fabbers is going, we are not really sure, and we are just going to let it take its course. I do think it is going to continue to grow, at least for a while. We are going to continue to throw workshops, too, either online or at different shops around the country. Our next workshop is going to be at Southeast Stone in Sanford, Florida. Workshops will last two to two and a half days, and will most likely begin on Thursday. Larger companies will probably send one or two people, whereas, smaller companies will likely take a couple of days off and send the whole crew.”

Let’s face it, there are really only two ways to learn: by your mistakes or the past mistakes of others. The All Slab Fabricators role is to be a resource for fabricators, tile setters and people in the industry as a whole. It’s also to bring awareness to others who are engaged in the industry, such as designers and architects. Got questions? The All Slab Fabbers just might have the answers. Give them a try on Facebook.

Chris Hildebrand opened the doors of Affordable Quality Marble and Granite in 2006 and built it the old-fashioned way — piece by piece. To see what hard work and planning has done for his company and his people, visit www.southcarolinagranite.com .