How Much Money Can Your Shop Make?

The Amount of Money Your Shop Can Make is Limited

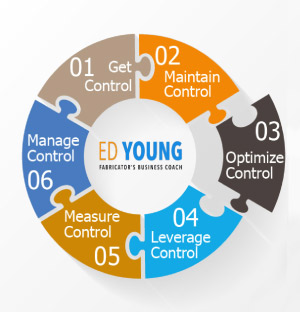

Ed Young

Fabricator’s Business Coach

Your shop does not have an infinite amount of capacity to make money – it is limited. You can only get so many kitchens or so many square feet through your shop in a day. However, even though your capacity is limited, there is always room to improve. So, the question is: Are you making all the money you can from your shop?

In my November Slippery Rock article Could You Use an Additional 10 Percent Capacity Right Now?, we defined capacity as how much value-added work you could execute in a day. As a quick review, value-added is the physical transformation of the raw material into a product your customer pays you for. While sawing is a value-added process step, the only true value-added (VA) activity at the saw is the time the blade spends in the stone. All other activities are non-value added (NVA). We also introduced you to a fellow named Tim Woods to help you root out those NVA activities. Tools to help you are available at www.FabricatorsCoach.com.

In my November Slippery Rock article Could You Use an Additional 10 Percent Capacity Right Now?, we defined capacity as how much value-added work you could execute in a day. As a quick review, value-added is the physical transformation of the raw material into a product your customer pays you for. While sawing is a value-added process step, the only true value-added (VA) activity at the saw is the time the blade spends in the stone. All other activities are non-value added (NVA). We also introduced you to a fellow named Tim Woods to help you root out those NVA activities. Tools to help you are available at www.FabricatorsCoach.com.

Since NVA activities reduce the amount of time you have to do VA work, how well you reduce the amount of NVA activities defines your capacity to make money. Simply put, reducing or eliminating NVA tasks increases your capacity to make money.

VA tasks generate money. NVA tasks consume money.

So, what’s the source of all this NVA work? You didn’t set out to have a shop full of activities that don’t make you money. Or did you…

How many times have you agreed to give a builder or homeowner an install date just to keep them happy? You knew it was likely the cabinets wouldn’t be installed soon enough for you to template and still have time to make the tops before installation. Or you knew the homeowner hadn’t selected slabs or a sink yet. Yet you gave in to their insistent plea.

Do you let your salespeople schedule templates and reward them for how many they schedule (sales bonuses)? They don’t have to fabricate the tops or install them. They are primarily concerned about how to hit their numbers – because that is the way you have set up their compensation. They aren’t concerned about travel time for the templater. No one is checking their jobs to be sure all decisions have been made so the templater can do his job properly.

Do you always buy the cheaper polishing pads even though the more expensive ones will get you to a finished edge quicker? (Have you even thought about which is quicker?)

Have you put off repairing your concrete floor because you don’t think you can afford the downtime required? Have you thought about how much it is costing you to NOT fix it (increasing the time it takes to move carts around the shop)? The same applies to corroded castors on carts, a forklift that sometimes starts – the list goes on.

Are you cutting jobs early to make sure everyone stays busy —not following the recommendations in last month’s article about strategically managing the level of work in your shop?

Do you have certain ‘pet’ or favored customers that you allow to interrupt your carefully planned schedule — ones that you give preferential treatment to?

All of these decisions create NVA activities that consume cash.

A recommendation in my November article was to pick a spot where you could see most or all of the processes in your shop. Hit that spot several times a day and note what percent of your machines/people are doing NVA work. Track this percentage over several days. This will give you a good idea of how well you are leveraging your capacity to do the VA work you customers pay you for.

As you start to tackle reducing or eliminating those NVA tasks, ask yourself why that task is happening in the first place. To effectively begin reducing the NVA work in your plant, you need to uncover the root cause for why that situation exists. A simple but effective way to do this is called the 5 Whys. Ask yourself why that task exists. Then ask yourself why that is true. The ask again, and again, and again. If you can do this objectively, you can drill down and find the true root cause of the issue. If you truly want to improve your shop, get some of your more engaged employees involved in this exercise. Be sure to bring your thickest skin to this discussion – you may need it.

As you start to tackle reducing or eliminating those NVA tasks, ask yourself why that task is happening in the first place. To effectively begin reducing the NVA work in your plant, you need to uncover the root cause for why that situation exists. A simple but effective way to do this is called the 5 Whys. Ask yourself why that task exists. Then ask yourself why that is true. The ask again, and again, and again. If you can do this objectively, you can drill down and find the true root cause of the issue. If you truly want to improve your shop, get some of your more engaged employees involved in this exercise. Be sure to bring your thickest skin to this discussion – you may need it.

You are paying for all the capacity in your shop. How well are you utilizing that capacity to make money in your business?

Combine these tools with the information in the rest of these six articles and you can free up 30 percent or more of the capacity you are already paying for. This means 30 percent more square footage through your plant every day. While doing that, you can also deliver a consistent short 5–or 6–day Template-to-Install lead time.

In next month’s article, we will talk about the role scheduling plays in making this work. Here’s an excerpt:

How much profit do you plan to make next Thursday? It may sound like a crazy question, but, if you think about it, your scheduler determines your ultimate potential to make a profit on any given day. So, I’ll ask again, how much profit has your scheduler planned for you for next Thursday? Next month we will talk about how to help the scheduler plan for you to make more money and better satisfy your customers.

As a fab shop owner, you deserve to have a business that makes you money and also allows you the time to enjoy it. To find out more about how to make more money and get your life back email me at Ed@FabricatorsCoach.com.

In addition to having run a countertop fabrication shop, Ed has also helped many fab shop owners become very successful.

He is a seasoned manufacturing manager and coach who has helped hundreds of companies from single person startups to large international corporations. As a former business owner, he understands the responsibility to make payroll while also satisfying customers. Contact Ed at Ed@FabricatorsCoach.com .