Do You Want More Profit From Your Shop?

Then Schedule It!

Ed Young

Fabricator’s Business Coach

How much profit do you plan to make next Thursday? I know it sounds like a crazy question. However, if you think about it, your scheduler really determines your ultimate potential to make a profit on any given day. So, I’ll ask again, how much profit has your scheduler planned for you for next Thursday?

How much profit do you plan to make next Thursday? I know it sounds like a crazy question. However, if you think about it, your scheduler really determines your ultimate potential to make a profit on any given day. So, I’ll ask again, how much profit has your scheduler planned for you for next Thursday?

OK, predicting next Thursday may too tough to do right now, so let’s make it easier and look at the past:

How much money did you plan to make yesterday?

How much did you actually make?

How do you know?

Since scheduling sets the maximum amount of money you can make in a day, you can’t afford to schedule your precious limited capacity if you aren’t absolutely sure you can execute to that schedule. To do otherwise means that you are planning to waste your capacity to make money. This means you shouldn’t schedule a job unless:

- The customer has already selected their material.

- The customer has signed off on seam locations.

- You already have the countertop material or are certain it will be at the shop in time to cut it.

- All sinks and faucets will be at the shop or on site.

- Faucet holes have been defined.

- The customer has signed off on all waivers.

- You are sure that cabinets are going to be set, when you’re at template stage.

- A customer-authorized decision maker will be on site for the template and for the install.

- Range/cooktop info is defined, templates are on hand, and the customer has signed off as needed.

- The customer has agreed that no other trades will be on site for either template or install appointments.

- Site access restrictions have been defined and addressed (key codes, etc.).

You can probably think of a few more.

While there are obvious things you need to do to make this happen, the customer has a critical role too. Consumers buy more cars and houses than they do countertops. This means customers likely don’t understand the countertop sales and production process. If you don’t want to risk your precious limited capacity, you need to help your customers understand their role in ensuring a successfully completed job. Setting those expectations starts by educating the customer at every opportunity. Expectations that the customer should have of your business as well as expectations you have of the customer should be spelled out early and often. Providing handouts are a good practice since you can’t be sure a customer has viewed the information on your web site.

While there are obvious things you need to do to make this happen, the customer has a critical role too. Consumers buy more cars and houses than they do countertops. This means customers likely don’t understand the countertop sales and production process. If you don’t want to risk your precious limited capacity, you need to help your customers understand their role in ensuring a successfully completed job. Setting those expectations starts by educating the customer at every opportunity. Expectations that the customer should have of your business as well as expectations you have of the customer should be spelled out early and often. Providing handouts are a good practice since you can’t be sure a customer has viewed the information on your web site.

How well you refine your sales and customer service processes to accomplish all this will determine how much money you can make in your business. You can have the best fab plant in the world with the most modern technology and the best workers and the best managers, but even that heavenly scenario cannot overcome being fed incomplete or ill-defined jobs. Tight, well-defined, and well-executed pre-production processes are essential to maximizing the amount of money you can make next Thursday.

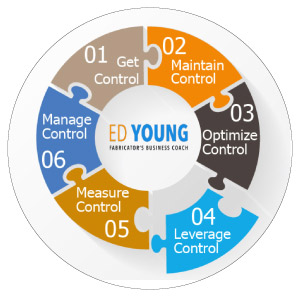

If you have been following this article series, by now you will have selected a constraint and set up buffers to manage the flow of work to the constraint. You are also applying VA/NVA analysis to non-constraint processes in order to drive the bottleneck to the constraint. This means you are starting to define the capacity of your shop and beginning to manage that capacity. You are beginning to leverage this new production management system:

- WIP (work in process – the number of jobs on the shop floor at one time) is decreasing.

- Lead times are getting shorter.

- The production team is beginning to focus on how they impact the constraint by watching for holes and fat in the buffers.

- You are getting control of the flow of work through your shop.

- TIM WOODS* is on a diet and isn’t eating up a lot of your capacity.

- You are seeing the capacity of your shop begin to increase.

- The chaotic noise level in your business should be noticeably lower.

This is article number four of six. These articles are designed to help you get predictability and control of your business. One outcome of using this system is you will have the ability to predict your P&L before the month is over. This means, about the middle of the month, you should be able to predict what your accountant is going to tell you on the 10th of the next month. You will know if you are on track to achieve the profit target you have set for the month – and you know this in time to make adjustments before the month is over. No longer are you driving while looking in the rear-view mirror. You can make effective proactive business decisions and accurately predict their impact. Next month we will dive into the critical few metrics needed to help you make that happen.

As a fab shop owner, you deserve to have a business that makes you money and also allows you the time to enjoy it. To find out more about how to make more money and get your life back email me at Ed@FabricatorsCoach.com.

In addition to having run a countertop fabrication shop, Ed has also helped many fab shop owners become very successful.

He is a seasoned manufacturing manager and coach who has helped hundreds of companies from single person startups to large international corporations. As a former business owner, he understands the responsibility to make payroll while also satisfying customers.