Manage to Get Your Life Back

If you don’t make a conscious decision to run your business, then it will run you.

If you don’t make a conscious decision to run your business, then it will run you.

Ed Young

Fabricator’s Business Coach

While it may look like it to some people, we all know that businesses don’t run themselves. A person (usually more than one) must understand what is happening in the business and take the actions required to adjust performance or there are consequences. Businesses that seem to run themselves have several factors in common.

First: There are a few key people in key positions that are very capable of performing their assigned roles.

I run into far too many fabricators that are struggling because they don’t have good capable people in critical roles. “Bob’s my brother-in-law and he does a decent job managing the shop,” just isn’t good enough anymore.

When you can’t find a qualified manager with industry experience, refusing to hire an experienced manager from outside the industry is short-sighted (none of us were born knowing how to fabricate tops). Most small businesses stall because the owner either can’t or won’t build a strong management team (and delegate authority). Having capable people in positions like production management, field management (template and install), and sales is a necessity (the size of your company will determine how many people are needed in these roles).

Jim Collins talks about the impact of having the right people in the right seat on the bus in his book Good To Great. While he refers only to large publicly traded companies, the same principles apply to your fab shop, no matter the size.

Second: The key people in the business spend part of their day working on the business and not just working in the business.

Spending all day in fire-fighting mode is exhausting. It feels critical right now, but it is threatening the future of your business. Everything in life is either growing and getting better or it is shrinking and declining. If it isn’t growing, your business is declining.

In order to grow, you have to spend time improving various aspects of your business. In the middle of the daily fire fight of running your business is admittedly a very tough time to stop, take a deep breath, and get your head above the fray so you can see what’s really going on. But it is essential to do this frequently if you want your business to grow.

Start by taking 30 minutes first thing in the morning two days a week to work on your business. Do this for a few weeks. Then switch to 3 days a week for a few weeks. Work your way up to spending an hour each day figuring out how to improve some aspect of your team, your management style, and your culture so performance of the business improves.

Third: The business uses a management system that helps them stay on top of current performance, track historical trends, and provide leading indicators.

Depending on the size of your business, your management system may include a software package to help manage the flow of jobs in your shop and give you key information. However, the management system should be more than just software.

To be effective, it must include a daily rhythm of activities to assess business performance and address identified issues. The frequency and level of detail for this assessment should be appropriate to each manager, but it looks something like this:

![]() Check the status of the buffer zones 3 times per day.

Check the status of the buffer zones 3 times per day.

- Visual controls on the plant floor are effective in making this a quick check (example: paint squares on the floor for each A-frame in the red zone if your constraint is Install).

![]() Check the performance of the constraint at least 3 time per day.

Check the performance of the constraint at least 3 time per day.

- Set up a white board or computer screen so this is continuously visible to everyone

![]() Check $T score from the previous day as early in the day as possible – post where everyone can see it.

Check $T score from the previous day as early in the day as possible – post where everyone can see it.

![]() Each morning (same time, place, attendees, agenda) hold a 15-minute stand-up meeting to communicate to the management team:

Each morning (same time, place, attendees, agenda) hold a 15-minute stand-up meeting to communicate to the management team:

- Constraint performance – how much $T did we score yesterday?

– Do we have any outstanding issues from yesterday that need to be addressed?

- Buffer health — where do we have holes or fat in each zone? Assign someone to address each issue.

- Any prior issues from other buffer meetings that haven’t been resolved.

- Backlog level – the number of days of jobs sold and ready for template.

- Guidelines for this meeting:

— This is a status meeting only – no problem-solving allowed.

— Check the status of each issue and assign one person to be responsible for resolving an issue.

— Problem solving will occur later as appropriate.

— This gives each key team member a sense of priorities for the day.

— Posting this information in a few key places in the business can be a great tool to keep everyone focused on the critical issues.

![]() Daily — Carve out one hour to improve some aspect of the business.

Daily — Carve out one hour to improve some aspect of the business.

- Do this individually and also as a group.

- This should include documenting and improving some part of a business process.

- This could include training.

![]() Daily — Plot $T vs $OE

Daily — Plot $T vs $OE

- Forecast month end P&L based on backlog and shop performance.

- Review with the management team weekly.

![]() Weekly — Take a safety walk through your plant to look for:

Weekly — Take a safety walk through your plant to look for:

- People wearing their PPE and using safe practices – praise and recognize them.

- Safety issues that need to be addressed.

- At least monthly – Make the same safety assessment at customer sites for templators and installers.

![]() Weekly — Get a status of the volume at each stage of your marketing and sales funnel – quantify in $T.

Weekly — Get a status of the volume at each stage of your marketing and sales funnel – quantify in $T.

- Analyze trends for each stage.

- Assess if you have enough volume at each stage to keep the constraint busy.

![]() Monthly — Communicate with the entire business about where things are and where they are going (impending challenges).

Monthly — Communicate with the entire business about where things are and where they are going (impending challenges).

- Don’t just talk – ask for questions from your folks and LISTEN to the answers.

- Recognize people who are modeling the behaviors you want to see more of.

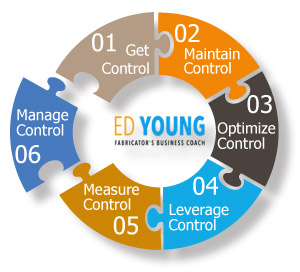

The six articles in this series form the basis of a robust and proven management system. This system gives you the information and tools needed to run the business very effectively – freeing up 30% of the capacity you are already paying for, reducing lead times, and reducing the chaos in your business. But this system won’t deliver results by itself – it requires capable people in key positions to make it work. Consultants are great tools to help you learn a different way of looking at your business, teach you new tools to help you run your business better, and challenge you to leverage them effectively. In the end, your management team has to execute effectively for your business to see the benefits.

As a fab shop owner, you deserve to have a business that makes you money and also allows you the time to enjoy it. To find out more about how to make more money and get your life back, email me at Ed@FabricatorsCoach.com.

For a link to the Management Rhythm Tool, scan the QR code below.